Orders & Worldwide

Orders & Worldwide

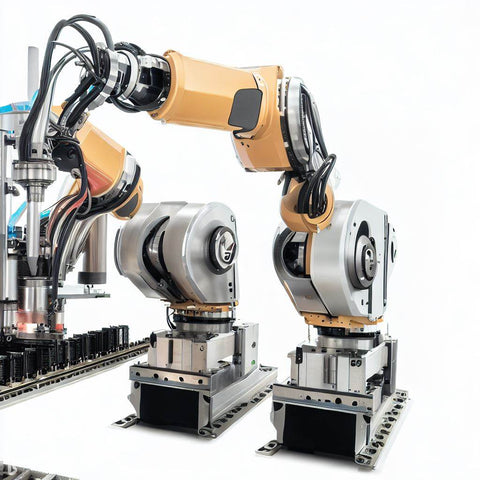

Industrial robotics involves the use of robotic systems within manufacturing and industrial settings. With their exceptional capabilities, industrial robots offer unparalleled advantages.

They enhance productivity, streamline processes, ensure precision, and contribute to improved safety for workers. Moreover, as technology advances, industrial robots become increasingly intelligent and adaptable.

Now these robots are capable of handling complex tasks with efficiency and accuracy.

The industrial robot industry is on track for remarkable growth and transformation. In 2022 the Global Industrial Robotics Market was valued at USD 48.5 billion.

With an estimated compound annual growth rate (CAGR) of 11.4% between 2023 and 2032, this market is projected to reach USD 142.8 billion.

This upward trajectory underscores the immense potential and lucrative opportunities ahead for the industrial robot industry.

Factors such as increasing labour costs, demand for improved productivity, and technological advancements drive this steady growth. Market growth is further fueled by the growing demand for industrial robots, especially in small enterprises.

Moreover, government regulations regarding hazardous materials and products encourage the adoption of industrial robots. By deploying robots in these sensitive areas, companies can ensure safer and more compliant handling practices.

Collaborative robotics is evolving rapidly thanks to computer vision and machine learning. Cobots, or collaborative robots, can pick up items in non-fixed positions with 3D vision and laser-triangulation techniques.

Various sectors have deployed these advanced cobots, including warehouses, hospitals, factories, and hazardous environments.

They are great for transporting hazardous goods, cleaning heavy equipment, and managing warehouse inventory.

Many notable companies dominate the cobots market, including FANUC, Yaskawa, ABB, KUKA, Techman Robot, AUBO Robotics, and Doosan Robotics. They have played a crucial role in driving cobot adoption and advancement.

Technological advancements and automation demand are poised to take collaborative robotics to the next level. Cobots will significantly improve efficiency, productivity, and safety by combining humans and robots.

Industrial robotics technology rapidly embraces artificial intelligence (AI) and machine learning (ML) capabilities. Integrating AI in industrial robotics enables robots to learn and adapt over time.

Robots can analyze vast amounts of data through ML algorithms, identify patterns, and optimize their performance accordingly.

This iterative learning process empowers robots to improve their accuracy, efficiency, and decision-making capabilities continually.

By incorporating AI into industrial robotics, robots can provide timely signals for maintenance, thus preventing costly downtime.

Leading companies like KUKA and Fanuc are actively driving the adoption of greater connectivity and AI in their industrial robots across various areas.

The Internet of Things (IoT) and robotics are revolutionizing the automation and robotics industries. This convergence gives rise to the Internet of Robotic Things (IoRT) concept.

IoRT creates a new paradigm in which robots become interconnected and intelligent entities, using IoT technology to enhance their capabilities.

By fusing sensor data and applying AI and ML algorithms, robots can analyze real-time information, learn from it, and make autonomous decisions to optimize their actions in the physical world.

This synergy between IoT, robotics, AI, and ML is a game-changer, empowering automation and robotic companies to achieve higher levels of efficiency, adaptability, and responsiveness.

The potential for robots to interact with working environments and dynamically adapt to changing conditions across various industries is vast.

As IoT continues to evolve and robotics becomes increasingly sophisticated, the Internet of Robotic Things holds immense potential for transforming how we view and utilize automation and robotics.

In the manufacturing industry, flexible and adaptable robots are in increasing demand. As production needs diversify, companies need robots capable of handling various tasks and adjusting to changing requirements.

The manufacturing sector is undergoing a major trend of collaborative automation, particularly for small and medium-sized businesses.

The use of cobots increases productivity and efficiency by allowing employees to collaborate on tasks. The demand for customization and integration services in robotics is also high.

Customization allows robots to meet specific manufacturing requirements, while integration services ensure smooth operation and implementation.

The healthcare industry is experiencing a significant transformation with robotics adoption. In surgical procedures, robots assist surgeons with precision and improve patient outcomes. With high accuracy, these robots can enhance surgical procedures and reduce errors.

Robots are also making an impact on rehabilitation and assistance. They facilitate therapy sessions and help patients regain mobility and independence. Robotic automation is transforming supply chain management and medical logistics.

Robots are used in healthcare facilities to control inventory, track medical supplies, and distribute essential items. Automation improves efficiency, reduces errors, and ensures timely delivery of critical supplies.

Therefore, robotics companies can design robots tailored to healthcare to provide the best care while maximizing profits.

Agricultural and food processing industries require robotics for enhanced efficiency and productivity. With precision farming techniques and autonomous agricultural robots, farmers can maximize crop yields.

The robots can perform tasks like soil analysis, seeding, and crop monitoring. Also, robots are essential to agricultural and food processing processes such as harvesting, sorting, and packaging.

They can efficiently handle delicate produce, sort items based on quality and size, and package them for distribution.

Food safety is another crucial aspect of robotics in agriculture and food processing. The robot can enforce quality control, detect contaminants, and maintain a hygienic production environment.

As a result, standards of food safety are improved, and contamination risks are decreased. Agriculture and food processing are large industries that demand robotics, so companies can exploit these opportunities.

There is a great deal of opportunity for companies to leverage robotics in every industry. To capitalize on these opportunities, companies must conduct thorough market research.

Robotics can contribute to the success of businesses by understanding their industry's specific needs. Whether it's manufacturing, healthcare, agriculture, construction, or any other sector, market research helps companies determine the right applications and solutions for their business.

The future of the industrial robotics industry looks promising, thanks to the rapid growth of automotive industries in emerging economies. To stay competitive in the market, businesses are increasingly automating their operations.

However, components such as teach pendnat, servo motors, servo drivers and sensors must function properly for robots to perform efficiently in industrial environments. Otherwise, your business operations could be delayed.

A reliable robotic part supplier is needed to handle all your emergency requirements. Here's where inRobots comes in.

inRobots has been a leading seller of robotic parts for many years, offering complete solutions. So when you need robot parts from leading brands like KUKA, ABB, Fanuc, etc., contact inRobots.

Source

https://market.us/report/industrial-robotics-market/

https://www.automate.org/a3-content/what-are-collaborative-robots

https://www.anolytics.ai/blog/applying-artificial-intelligence-and-machine-learning-in-robotics/

https://www.analyticssteps.com/blogs/internet-robotic-things-robotics-iot

https://www.intel.in/content/www/in/en/healthcare-it/robotics-in-healthcare.html

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}

Leave a comment on this topic